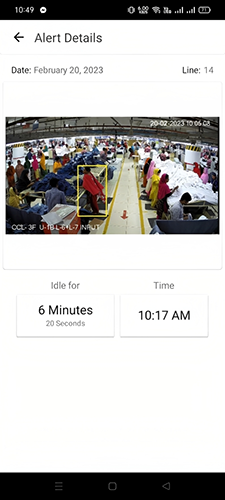

In a factory environment, assembly line stoppages due to material shortages, equipment breakdowns, or idle workers can significantly hamper productivity and result in financial losses. Early detection and resolution of these issues are critical to maintaining an efficient production process.

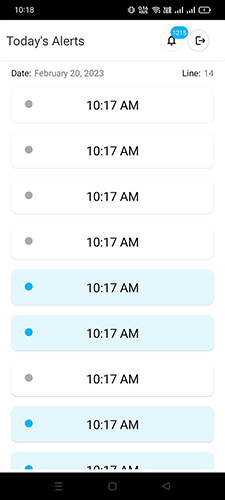

Infolytx presents OptiLine™, a powerful application that employs AI and Machine Learning to detect and alert factory supervisors of assembly line stoppages in real time. It leverages CCTV feeds and sophisticated Machine Learning models to identify idle workers, material shortages, or equipment malfunctions, serving as an intelligent and proactive monitoring tool.